This high-precision laser system specializes in glass and mirror processing, integrating laser marking, drilling, and engraving. It enables efficient, automated, and precise operations, delivering professional solutions for multiple industries.

As mainstream glass laser processing equipment, it works with glass/mirror materials of various thicknesses and specs. With no physical contact or stress damage during processing, it ensures finished product flatness and precision, meeting high production standards.

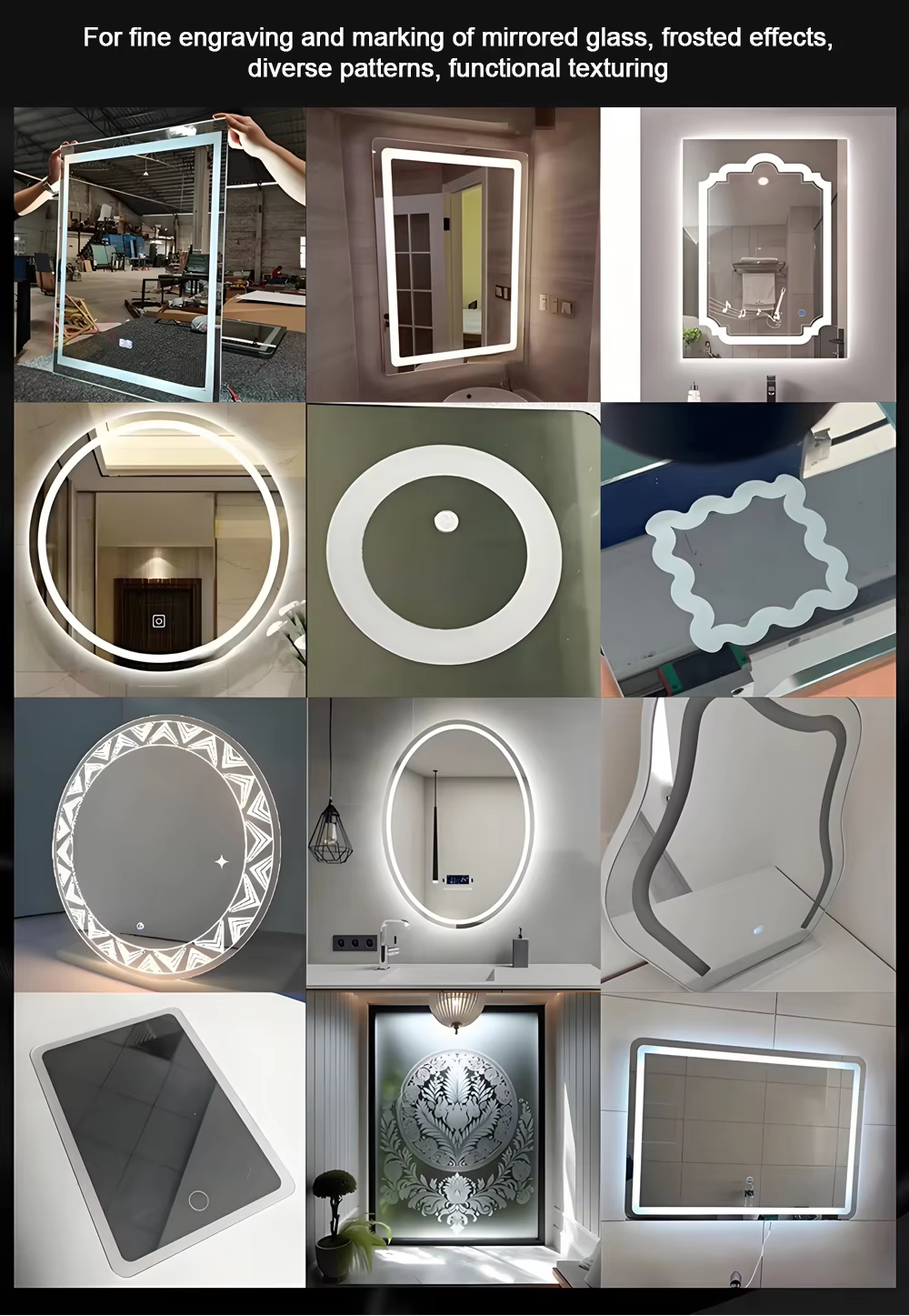

Widely used in glass manufacturing (finished glass marking), construction (curtain wall glass drilling/frosting), automotive (window glass precision processing), and home decoration (mirror engraving/personalized marking), it boosts efficiency, cuts labor costs, and fits both large-scale mass production and customized needs.

Product Features

1. Advanced Fiber Laser Technology: Micron-Level Precision, Zero Damage

Equipped with a high-power fiber laser source, it has a positioning accuracy of ±0.01mm and a service life of over 100,000 hours. The non-contact "cold processing" mode controls the heat-affected zone to ≤5μm, reducing glass edge chipping and cracks. The marks are permanently wear-resistant without damaging the integrity of the glass.

2. Multi-Functional Integrated Processing: Full-Scenario Adaptation

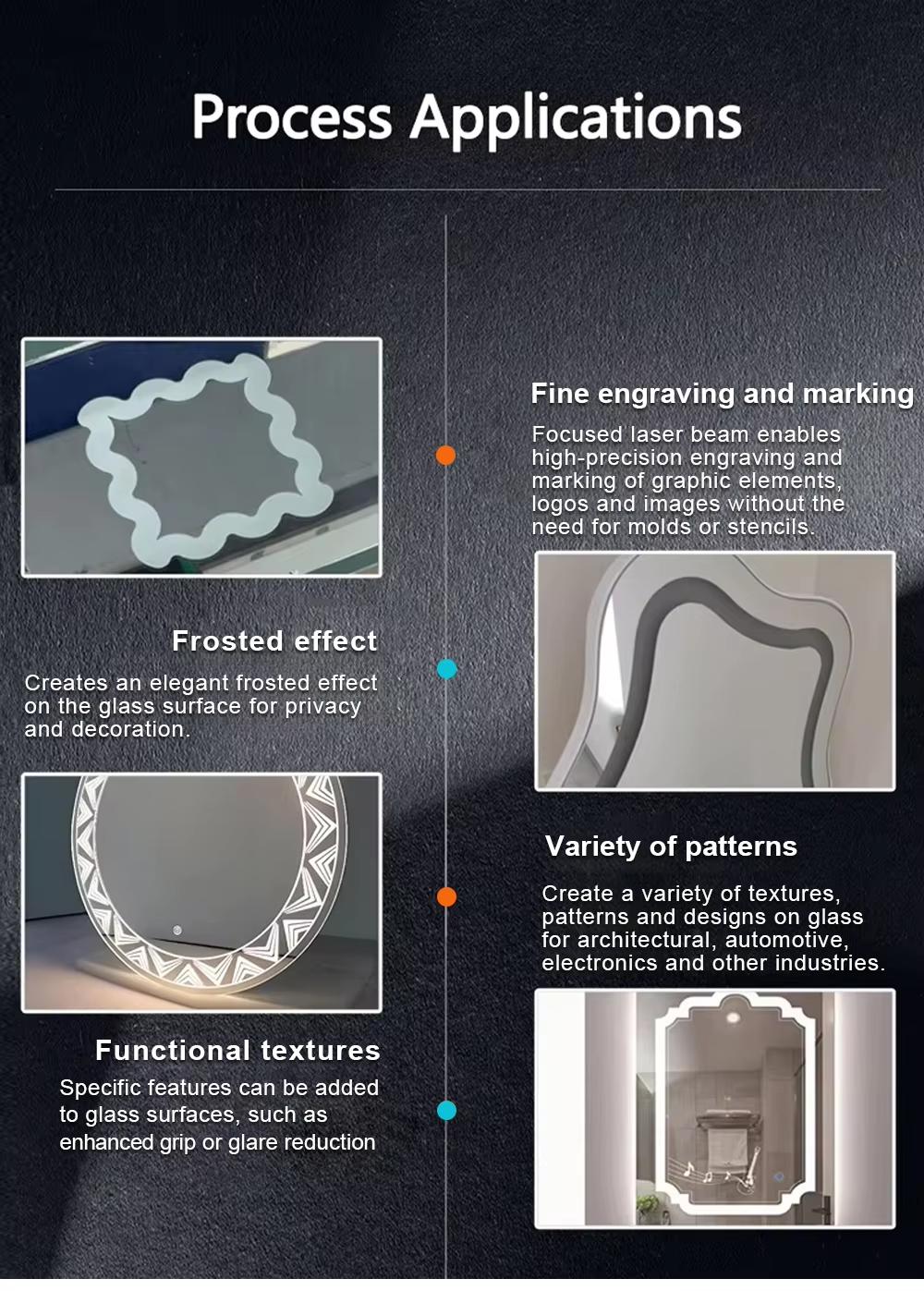

Laser Marking: Engraves complex patterns, logos, barcodes, and text, meeting both decorative and traceability needs;

Sandblasting & Frosting: Creates a fine frosted surface, suitable for architectural curtain walls and home mirrors;

Drilling & Cutting: Precisely processes special-shaped holes and curves. Cutting 12mm glass without stress cracking, with edge roughness Ra ≤0.5μm, no secondary grinding required.

3. High-Speed Precision Control: Full-Material Compatibility, High Efficiency

Integrated with a CNC system and a high-speed scanning galvanometer, the cutting speed is 30% or higher than that of traditional equipment, supporting 24/7 continuous production. Compatible with 0.1-12mm tempered glass, laminated glass, coated glass, and mirrors, meeting precision standards of multiple industries.

4. Intelligent Control System: Easy to Use, Customizable

Intuitive visual software supports import of DXF/AI/PLT/BMP formats, allowing custom solutions without programming. Real-time monitoring + automatic parameter adjustment enables novices to control complex processes accurately.

5. Eco-Friendly & Energy-Saving Design: Cost Reduction & Green Production

Low-power technology reduces comprehensive energy consumption by 40%; intelligent path planning increases material utilization rate from 72% to 88%. Standard dust and fume extraction system ensures no dust pollution, complying with green manufacturing requirements.

Main parameters

| Item | Detailed |

| Application | Smart mirrors grinding, mirror/glass perforation, mirror foil removal |

| Applicable Material | Glass /Metal |

| Power | 120W |

| Cutting Area | 1300mm*2500mm(can customizable) |

| Cooling Mode | WATER COOLING |

| Processing thickness | 1-50mm |

| Machining travel speed | 0~40 m/min |

| Laser type | Anti High Reverse Full Power Metal Fiber Laser Generator |

| Structural Cavity Material | Aircraft aluminum precision CNC grinding, surface sandblasting, oxidation hardening treatment |

| Cutting precision | ±0.01mm |